The Red Head Brass Commitment to Quality and Safety in Storz Couplings

Fabricated from seamless extruded and forged 6061-T6 aluminum, then hardcoat anodized per MIL-A-8625 Type III, Class 1 — our Storz couplings have no peer.

Review our quality, then insist on the best — Storz couplings from Red Head Brass.

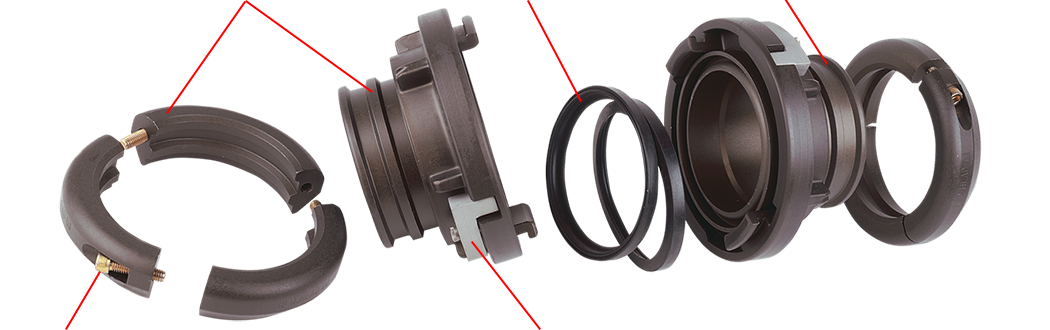

Storz tail piece and collars are machined from 6061-T6 aluminum seamless extrusions.

Meets ASTM B221 requirements.

High quality molded Storz gaskets made using Buna-N material — resistant to most oils, gasoline, acids and greases.

Storz Heads up to 6" are forged 6061-T6 aluminum to Spec. SAE-AMS-QQ-A-367 & ASTM B247. Complies with DIN standards.

All collars are assembled with 3/8-16 socket head cap screw made of a high tensile alloy to ASTM A574 with a Zinc Yellow Dihchromate coating to QQ-Z-325, Type II.

Lock Lever is an investment casting of 304 stainless steel ASTM A743. Lock Lever Spring is 316 stainless wire passivated AISI 316. Lock lever mounted with 18-8 stainless steel shoulder bolt.

All aluminum components are Hardcoat Anodized per MIL-A-8625 Type III, Class 1. Permanent part identification stamped or forged prior to hardcoat.

Red Head Aluminum Storz Couplings: Specifications

Aluminum Storz Hose Couplings shall consist of Storz coupling heads machined from forged 6061-T6 aluminum and coupling components fabricated from seamless extruded 6061-T6 aluminum.

All aluminum components shall be hardcoat anodized per MIL-A-8625 Type III, Class 1.

Part identification shall be permanent and stamped or forged prior to hardcoat.

All 4", 5" and 6" coupling heads shall include a stainless steel external spring-loaded lock.

Storz gaskets shall be molded Buna-N rubber.

For field reattachable couplings add: the couplings shall have a tail piece sized to match hose diameter and matching segmented, bolted clamp collars fabricated from seamless extruded 6061-T6 aluminum.

Couplings and components must meet the requirements of NFPA 1963.

For expansion type couplings add: Swivel and tail gaskets shall be lathe cut ozone free EPDM or synthetic rubber.

Expansion rings must be smooth and well rounded soft anneal seamless red brass per UNS 23000.

Couplings and components must meet the requirements of NFPA 1963.