The Red Head Brass Commitment to Quality and Safety in Aluminum Couplings

All aluminum couplings are not created equal.

The Red Head Brass quality advantage is built into every aluminum coupling we sell.

Made from 6061-T6 aluminum seamless extrusions. Meets ASTM B-221 and provides the strength to meet Federal Spec A-A-59227A: Couplings shall not distort, bind, or become inoperative when subjected to a 3000 pound radial compression load as specified in 3.4.4.

Red Head aluminum couplings are Hardcoat Anodized per MIL-A-8625 Type III, Class 1. Hardcoat is a dense coating formed by converting the surface of the aluminum alloy into a hard aluminum oxide.

This process complies with NFPA 1963, 4.12 Corrosion Resistance and provides the completed part with a durable surface that resists corrosion, abrasion, reduces electrolysis and prevents excessive thread wear.

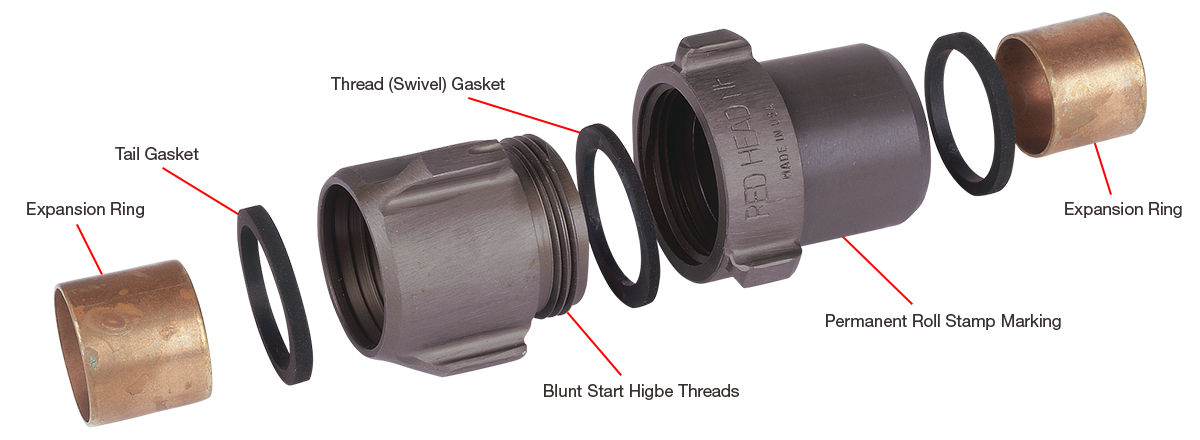

Expansion Rings

- Included with each coupling and are made from seamless soft anneal red brass tubing, UNS 23000 for maximum expansion without danger of breaking.

- Chamfered edge prevents cutting of hose.

- A-A-55535: Expansion rings shall be free from scale, grooving, indentations, cracks, scores, dents, and burrs. The ends shall be round and smooth.

Permanent Roll Stamp Marking

- Part identification is stamped into the aluminum prior to hardcoat finish.

- Complies with USDA 5100-190 C 3.4.

Gaskets

Lathe cut synthetic or EPDM gaskets are included with each coupling:

- NFPA 1963, 7.1: Each coupling shall be equipped with a resilient thread gasket with a durometer of 70 +/-5, Shore A.

- NFPA 1963, 7.3: Each coupling shall be equipped with a resilient tail gasket with a durometer of 60 +/-5, Shore A.

Swivels:

Are attached as follows:

- 1" thru 2 1⁄2" with 6061-T9 aluminum piston rings.

- 3" & 3 1⁄2" with #316 stainless steel ball bearings.

- 4" thru 6" with 6262-T9 aluminum roller bearings.

This construction is compliant with the following:

- A-A-59227A 3.4.1: Couplings shall withstand a hydrostatic pressure of 1000 PSI.

- A-A-59227A 3.4.3: Couplings shall not be mechanically damaged at their thread or swivel connection or separated from the hose when a pull load of 2000 pounds per each inch of hose diameter is applied.

- NFPA 1963 4.9: Couplings shall be capable of being dropped up to 6 feet (3 times) without deformation or damage. Meets low lead requirements.

Threads

Conform to the following specifications, including a blunt start first thread known as the Higbee located in line with the Higbee indicator on the lug.

- Federal Handbook H28/10

- USDA 5100-190 C Tables 1– 4

- NFPA 1963 5.1 thru 5.6.4

- UL 236 8.1 thru 8.2

Red Head Aluminum Couplings: Specifications

Hose Couplings shall be fabricated from seamless extruded 6061-T6 aluminum and hardcoat anodized per MIL-A-8625 Type III, Class 1.

Male end lugs shall have "LA Taper".

Threads shall be blunt start Higbee cut with indicators on adjacent lugs.

Part identification shall be permanent and stamped prior to hardcoat.

Swivel attachment must be metal rings or bearings, not swaged.

Gaskets shall be lathe cut ozone free EPDM or synthetic rubber.

Expansion rings must be smooth and well rounded soft anneal seamless red brass per UNS 23000.

Couplings and components must meet the requirements of NFPA 1963.