The Red Head Brass Commitment to Quality and Safety in Aluminum Adapters

All aluminum adapters are not created equal.

The Red Head Brass quality advantage is built into every aluminum adapter we sell.

All Red Head aluminum adapters are made from 6061-T6 aluminum seamless extrusions (Meets ASTM B221), and are hardcoat anodized per MIL-A-8625 Type III, Class 1.

This MIL-spec hardcoat provides the completed part with a durable surface that resists corrosion, abrasion, reduces electrolysis and prevents excessive wear on the threads.

The hardcoat complies with NFPA 1963, 4.12 Corrosion Resistance.

Plain or anodize, painted or powder coated finishes are never used.

Red Head Aluminum Adapters: Specifications

Aluminum adapters shall be fabricated from seamless extruded 6061-T6 aluminum and hardcoat anodized per MIL-A-8625 Type III, Class 1.

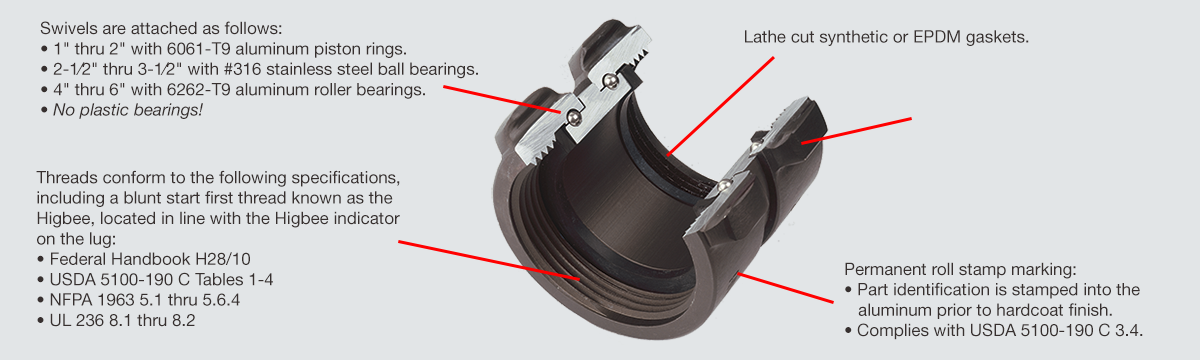

Swivel attachment must be metal rings or bearings, not swaged.

Threads shall be blunt start Higbee cut with indicators on adjacent lugs.

Part identification shall be permanent and stamped prior to hardcoat.

Gaskets shall be lathe cut ozone free EPDM or synthetic rubber.

Adapters and all components must meet the requirements of NFPA 1963